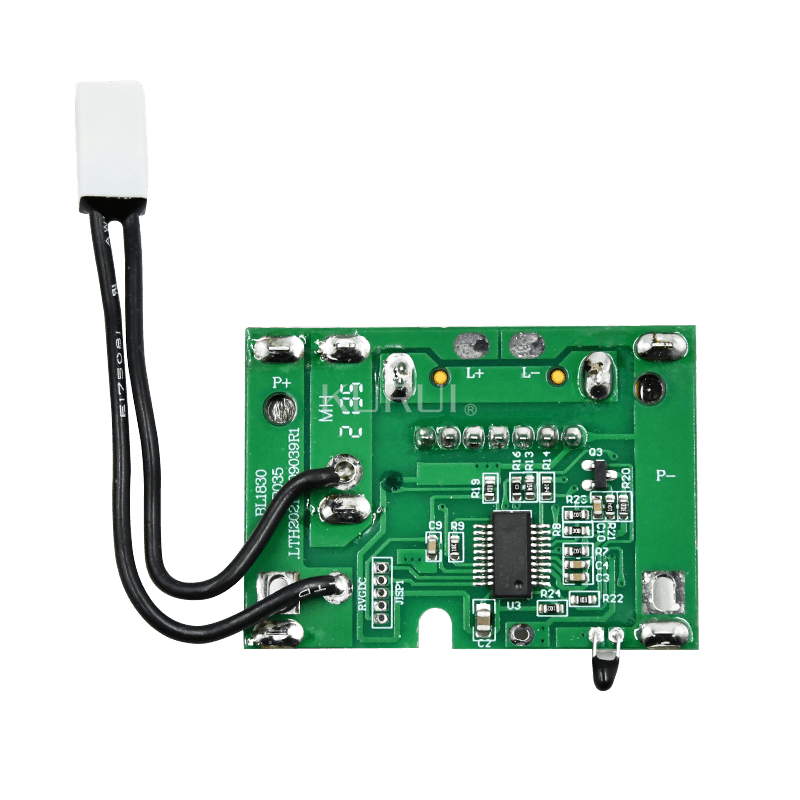

As a reliable manufacturer specializing in designing and producing battery protection boards, we custom many boards for worldwide customers. In this video, we will show you one of our customized board, model XR42. And we will also take you around the automated SMT assembly manufacturing process.

Products recommended in this video: Protection Circuit Board XR42: https://kuruipcba.com/product/battery-protection-board-xr42/

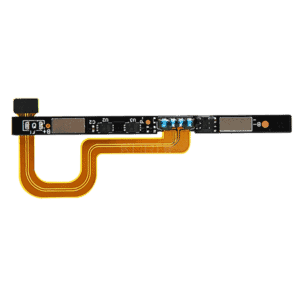

We’re focusing on designing and producing battery protection circuit board for all kinds of batteries. Today we’re gonna to show you one of our customized BMS board for mobile battery. The model is XR42. The board is made of flexible board and rigid board. You can see the details above. Over here, there’s a small tray of XR42 board. Batteries will be protected from over voltage, over current, and over discharge by the battery management system.

We will have a quick view our automatic SMT assembly workshop helping you to understand the process better. Automatic Solder Paste machine will print solder paste on the bare printed circuit boards. The function is to connect components on the board. This process is crucial for the quality of soldering the electronic components to the board. Therefore, we will use auto SPI machine to detect the board after solder paste. Automated picking and placement of the SMDs on the PCB, using a machine that holds the PCB, and places the components precisely where they belong. Through a conveyor, the boards are transported to a reflow oven. The temperature inside the oven is much higher than the melting point of the solder. It will melt the solder and ensure the components are soldered correctly. Auto AOI machine scan board surface via high-definition cameras. Differences, abnormalities, or even errors can be clearly identified at any time.