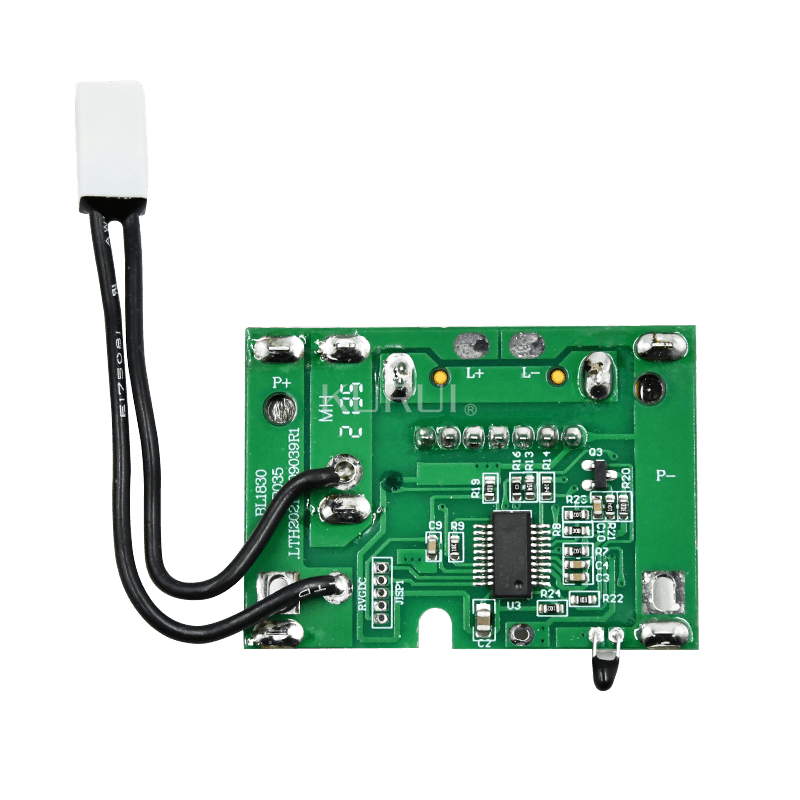

Overcharge Protection and Recovery

When the voltage of any cell is higher than the setting value of the single cell overcharge voltage, and the duration reaches the single cell overcharge delay, the system enters the overcharge protection state, turns off the charging MOS, and battery will cannot be charged.

After the single cell overcharge protection, when the voltage of all cells drops below overcharge recovery value of the single cell, the overcharge protection state will be released. It can also be discharged by discharge.

Overall Overcharge Protection and Recovery

When the overall voltage is higher than the overall over-voltage setting value, and the duration reaches the overall overcharge delay time, the system enters the overcharge protection state, turns off the charging MOS, and the battery cannot be charged. When the overall voltage drops below the recovery value of the overall voltage over-voltage protection, the overcharge protection state will be released, and it can also be released by discharge.

Over-discharge Protection and Recovery

When the voltage of any cell is lower than the setting value of the single cell over-discharge voltage, and the duration reaches the single cell over-discharge delay time, the system enters the over-discharge protection state, turns off the charging MOS, and battery will cannot be charged.

The over-discharge protection state can be released via charging the battery after single cell over-discharge protection.

Overall Over-discharge Protection and Recovery

When the overall voltage is lower than the overall over-discharge setting value, and the duration reaches the overall over-discharge delay time, the system enters the over-discharge protection state, turns off the charging MOS, and the battery cannot be charged.

The over-discharge protection state can be released via charging the battery after overall over-discharge protection.

Over-current Protection and Recovery via Charging

When the charging current exceeds the charging over-current protection current and the duration reaches the charging over-current detection delay time, the system enters the charging over-current protection state and battery cannot be charged. After the charging over-current protection occurs, it will automatically recover after a delay. If automatic recovery is not required, the corresponding release time can be set longer, and the charging over-current state can also be released by discharging.

Over-current Protection and Recovery via Disharging

When the discharging current exceeds the discharging over-current protection current and the duration reaches the discharging over-current detection delay time, the system enters the discharging over-current protection state and battery cannot be charged. After the discharging over-current protection occurs, it will automatically recover after a delay. If automatic recovery is not required, the corresponding release time can be set longer, and the discharging over-current state can also be released by discharging. Discharge has two-level over-current protection function, which has different response speeds for different current values, and protects the battery more reliably.

Thermal Protection and Recovery

Charge and Discharge High Temperature Protection & Recovery

When the NTC detects that the temperature of the battery cell surface is higher than the setting value of high temperature protection during charging and discharging, the battery management system enters the high temperature protection state, the charging or discharging MOSFET will be turned off, and the battery pack cannot be charged or discharged in this state.

When the temperature of the cell surface drops to the high temperature recovery setting value, the battery management system recovers from the high temperature state and re-conducts charging and discharging MOS.

Charge and Discharge Low Temperature Protection and Recovery

When the NTC detects that the temperature of the battery cell surface is lower than the setting value of low temperature protection during charging and discharging, the battery management system enters the low temperature protection state, the charging or discharging MOSFET will be turned off, and the battery pack cannot be charged or discharged in this state.

When the temperature of the cell surface increases to the high temperature recovery setting value, the battery management system recovers from the low temperature state and re-conducts charging and discharging MOS.

In static state (no charge and discharge), if the temperature rises or falls to the protection board, the protection board will not make any protection action until the system detects that there is current, and then makes the corresponding protection action.

Balancing Function

The battery management system uses the resistance bypass method to balance the cells. During the charging process, the voltage of the highest single cell of the battery pack reaches the setting balancing starting voltage value, and the voltage difference between the minimum voltage and the maximum voltage of the single cell of the battery pack is higher than the setting value. Both conditions is enabled, the balancing function of the cells start to working. And the two adjacent balancing cannot be enabled at the same time. When the balance is started, the charging current for the high-voltage cells is reduced, and the reduced current is the balance current setting by the management system.

The balancing stops when the cell voltage difference is less than the setting value. Charge balance mode and static balance mode can be set.

Capacity Calculation

The SOC calculation of the battery pack can be accurately performed by integrating current and time. The full capacity and cycle capacity of the battery pack can be set through the host computer, and the capacity can be automatically updated after a complete charge and discharge cycle. It has the function of calculating the number of charge and discharge cycles. When the accumulative discharge capacity of the battery pack reaches the set cycle capacity, the number of cycles increases once.

Note: For newly installed batteries, please set the nominal capacity and cycle capacity according to the battery capacity, and carry out a capacity study, otherwise there may be a problem of inaccurate capacity. Capacity learning operation: first fully charge to over-voltage protection, then discharge to under-voltage protection, and then charge it again.

Sleep function

When the protection board is in static state (no communication, no current, no balance and over-voltage protection.) After a delay of 1 minute, it will enter the sleep state. After entering this state, the protection board only reduces the frequency of detecting voltage and current and its own power consumption. There is no impact on customer use. Communication, dial switch, charging and discharging can automatically exit the sleep mode.

Storage Environment

The BMS protection board should be stored in a clean and well-ventilated warehouse with an ambient temperature of -5°C~+40°C, a relative humidity of not more than 70%, and the air must not contain corrosive gases and media that affect electrical insulation, and must not be affected by any Mechanical shock or heavy pressure. Avoid direct sunlight, and the distance from the heat source (heating equipment, etc.) should not be less than 2m. Under the above storage conditions, the BMS protection board can be stored for one year.

Important Notes

1) This battery management system cannot be used in series.

2) When multiple battery packs (which are using this battery management system) are connected in parallel, you should make sure that the maximum voltage difference of each battery pack before parallel connection is less than 3V.

3) When multiple battery packs (which are using this management system) are used in parallel, the total charging inrush current of the adapter may be applied to a single battery pack. It should be ensured that the total charging inrush current of the adapter does not exceed the maximum value of the charging inrush current of a single management system.

4) The short-circuit protection function of this management system is suitable for various application and conditions, but it does not guarantee that it can be short-circuited under any conditions. When the total internal resistance of the battery pack and the short-circuit loop is less than 40mΩ, the capacity of the battery pack exceeds the rated value by 20%, the short-circuit current exceeds 400A, the inductance of the short-circuit loop is very large, or the total length of the short-circuit wire is very long, please test to determine whether this management system can be used.

5) When welding the battery lead wires, there must be no wrong connection or reverse connection. If it is indeed connected incorrectly, the circuit board may be damaged and needs to be re-tested before it can be used.

6) During assembly, the battery management system should not directly touch the surface of the cell to avoid damage to the circuit board. Assembly should be firm and reliable.

7) During usage, be careful not to touch the components on the circuit board such as lead tips, soldering iron, solder, etc., otherwise the circuit board may be damaged.

8) During usage, pay attention to anti-static, moisture-proof, waterproof, etc.

9) Please follow the design parameters and usage conditions. It must not exceed the values in this specification sheet, otherwise the management system may be damaged.

10) The parameters, functions and shapes in this specification are for reference only, and the actual protection board shall prevail.

11) After the battery pack and the management system are assembled, if you find that there is no voltage output or charging is not possible after the first power-on, please check whether the wiring is correct.